Ultrasonic flow meter adopts advanced multi-pulse technology, signal digitization processing technology and error correction technology, which makes the flow meter more adaptable to the industrial scene environment, and the measurement is more convenient, economic and accurate. It can be widely used in petroleum, chemical, metallurgy, electric power and other fields. At present, ultrasonic flow meter are getting more and more attention from various enterprises.There must be a manual for the reasonable use of each product, and ultrasonic flowmeter is no exception. Attention should be paid to the following points in its use. First of all:

1) it is necessary to use the power supply voltage specified in the flowmeter product manual, and use the voltage other than the specified one, which is easy to cause potential safety hazards such as switch misoperation, damage, electric shock and fire;

2) never use the load exceeding the maximum load that the switch can bear;

3) when the circuit is struck by lightning and the inductive load or large load is switched on or off, very high operating over-voltage is often generated. This instantaneous over-voltage (or over-current) is called surge voltage (or surge current), which is a kind of transient interference. Because there is no surge protection device in the output part of the switch, the reverse voltage will damage the switch. When directly driving relays, solenoid valves and other loads that will generate surge voltage, products with built-in surge absorbing element model shall be used. Therefore, in the installation and use of the product, it is better not to use the load that will generate surge voltage, the output part of the switch, because there is no surge protection device, so the reverse voltage will damage the switch. When the direct drive relay, solenoid valve, etc. will produce;

4) pay attention to the flow measurement and the maximum use pressure: if the flow exceeds the specified range, the flowmeter will be damaged. In addition, if the maximum use pressure is exceeded, the switch will also be damaged. In particular, do not exceed the specified pressure of the water impact point;

5) before setting the product, the pipeline to be tested shall be filled with water, especially when the water is installed from the bottom to the top;

6) use flowmeter products in the range of specified flow range. When it is used outside the flow measurement range, it can not produce the Karman vortex, so it is abnormal to measure;

7) pay attention to the internal pressure drop of the switch. When the switch is used below the specified voltage, the phenomenon that the load does not act even if the flowmeter works normally will occur.

8. During installation and commissioning, the pipeline shall be filled with water, and the pipeline shall be vertical as far as possible, and the water flow shall be upward

In fact, no matter what product it is, as long as it is operated according to the product manual, it will not have any problems in general, but the premise is that it must be operated according to the relevant product manual flowmeter

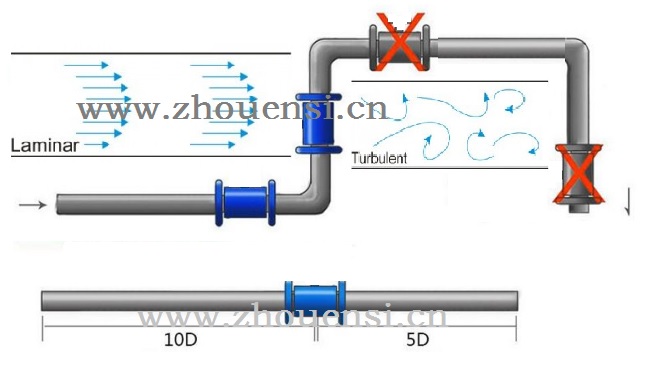

EU-108 Ultrasonic Flow Meter is a fixed mounted flow meter, the flowme...

7. In liquid installations, pressure pulsations can be a problem. Therefore, Protect meters from pressure pulsations and flow surges.

8. As much as possible, avoid strong electromagnetic fields in the vicinity of the Flow meter.

9. Install flow control or flow limiters downstream of the meter

10. Where vortex or corkscrew flow is expected, increase inlet and outlet sections or install flow straighteners.

11. Where it is not practical to meet the required straight pipe runs for the flow meter, you may consider using flow conditioners or straighteners.

12. Install two or more meters in parallel if the flow rate is too great for one Meter.

13. Every flow meter installation should provide allowance for the expansion of the pipe work.

14. Make sure there is sufficient clearance for installation and maintenance work to be done on the flow measurement system. When you see the space for work and maintenance in most practical installations, you wonder whether this point was ever considered at all

15. To enable meters to be removed for servicing without station shutdown,provide a by-pass line

16. Where possible provide proving connections downstream of the flow meter regular in-situ calibrations.

17. Never install a flow meter on the pump suction side.

Contact: Mr.Robert

Phone: 0086-13166369204

Tel: 400-852-8332

Email: hongkong@ayite.net

Add: Building 17 &22, No.2928, Chuan Zhou Highway, Shanghai, 201319, China